Stabilization of subsided floors and foundations

Cracks in the internal or external walls of the house and slanted floors are the primary danger signs that the building’s supporting structures have begun to subside. Cracks can appear in walls and floors of a building as a result of foundation settlement caused by weakening of the ground below the building. In order to remove the cracks it is necessary to first and foremost eliminate the reason that caused them, i.e. to reinforce the ground and raise the foundation to the design height. The easiest way to do that is to use URETEK geopolymer injection technology.

Free consultation

URETEK innovative injection technology with geopolymer resins offers effective solutions for soil compaction and load-bearing capacity stabilization, raising and re-leveling of the house foundation and floor. Other traditional solutions require reconstruction of the foundation, which is a significantly more expensive, time-consuming and obstructive process.

When it comes to the safety and condition of the house, the most important bearing role is the foundation. Unfortunately, foundation and soil subsidence is a frequent problem, which in turn can damage the building’s structure, floor and foundation systems, and strongly reduce the property’s value.

If the house subsiding process is not stopped as soon as possible, it can lead to even greater risks and costs in the future:

- the energy efficiency of the building decreases

- malfunctions of heating and electrical systems occur

- burst water pipes

- moisture and mold enter the building

- the value of the property decreases

HOW TO UNDERSTAND THAT THE HOUSE IS SUBSIDING?

- cracks in the interior and exterior walls and floors of the house

- the floors subside or are slanted, i.e. the skirting boards diverge

- windows and doors are out of level and their free movement is prevented

- the wallpaper has started to wave or peel (probably cracks are hidden under the wallpaper)

- the formation of increasingly large puddles around the perimeter of the house

House subsidence can be caused by weak subsoil, poor compaction of the soil before the start of construction works, excessive load on the floor, vibration, insufficient drainage system, trees growing near the house or the bursting of an underground water pipe, as a result of which water washes away fine particles from the soil.

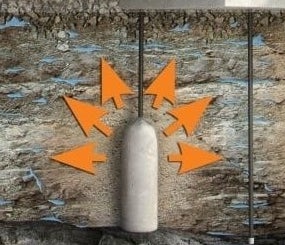

URETEK technical team uses patented two-component geopolymer resins in their work, which are injected through 10-12 mm diameter drill holes into the soil under the foundation or floor, restoring the soil’s bearing capacity and raising the subsided structure back to the original designed height with an accuracy of 1 mm. Geopolymer resins find their way into the voids created in the soil, then solidify in the soil, ensuring sufficient stability and stopping the house from further subsiding.

Before starting the work, the underfloor heating and sewage systems in the house are identified.

How do we resolve subsidence in just 1-2 days?

1. OUR EXPERTS DRILL HOLES IN THE AFFECTED AREA The drill holes are just 16mm wide and often we don’t even need internal access. |

2. WE INJECT A SPECIAL GEOPOLYMER RESIN In a quick and easy process we inject a special geopolymer that will expand and harden to support the property. |

3. THE RESIN INSTANTLY HARDENS LIKE CONCRETE Within just 20 seconds the geopolymer has expanded to fill any voids and stabilise the ground and is already 90% cured. |

THE CONCRETE FLOORS CAN BE LIFTED AND FOUNDATIONS STABILISED You’ll see the results instantly. Often cracks disappear and doors unstick as we raise the property. |

FAST, CALM AND CLEAN TECHNOLOGY

- We stop the subsiding of the house within 1-2 days without disturbing the customer’ s daily life.

- The work is not accompanied by dust, excessive noise or other disturbing elements.

- No demolition and excavation work is carried out, no construction waste transport is required.

- The work process does not cause damage to the building or yard area – the customer’s home, yard and beds remain clean and tidy.

- The materials do not pose a threat to people or the nature around us.

URETEK provides 50 years of warranty on its patented materials.

For a free consultation and to assess the condition of the load-bearing structures of the building contact our experienced specialists.

SEND INQUIRY